eTuft (Robotic Tufting Machine or Robotuft®) is an advanced robotic tufting machine for the production of fashionable tufted carpets and custom-made artificial grass. This state-of-the-art robot is ideal to handle your single orders or ongoing production as well as sampling.

In combination with eDesigner and eHMI (HMI for tufting robots) software you will find with our tufting solution the perfect combination for creative and cost-effective carpet and custom-made artificial grass production.

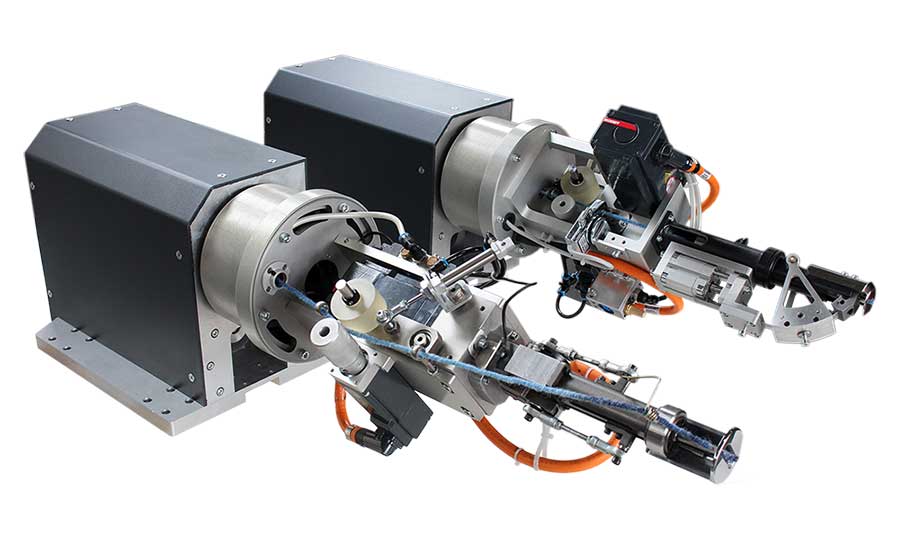

Mechanical tufting head with nonstop cut/loop changeover

This unique mechanical tufting head is ideal for low cut pile tufting (~9mm before shearing) has unique features as below:

- Automatic and nonstop changeover between cut and loop pile

- Tufting on a variety of backing fabrics

- Tufting designs with very small details

- Ultra high density tufting

- Deliberate Over-tufting

- Tufting in short cut pile height (9mm cut pile before shearing)

- Loop pile: 4mm–15 mm

- U-tuft Cut Pile: 9-16mm

- Y-Scissor cutting principle

- Working without pressured air

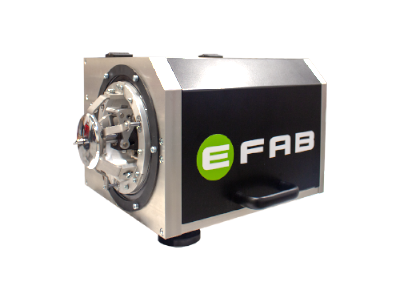

Interchangeable Tufting-Gun Mechanism

eTuft robots are equipped with an innovative Interchangeable Tufting-gun Mechanism.

EFAB´s latest development – the unique interchangeable tufting head – combines the advantages of both mechanisms:

- Mechanical tufting gun can tuft on a variety of backing fabrics and produce very detailed or over-tufted designs with high densities in short pile height.

- The pneumatic gun can compensate for the supposed disadvantages by switching between cut and loop pile automatically (nonstop changeover),

tufting with different pile heights (3D effects) or J-tuft.

To benefit from both mechanisms, EFAB has invented an Easy Docking System: the operator can change the tufting gun from mechanical to pneumatic one easily by opening just 6 screws and without any electrical hassle.

Mechanical tufting gun

- Y-Scissor cutting principle

- Loop pile: 4mm–15 mm

- U-tuft Cut Pile: 9-18mm

- Deliberate Over-tufting

- Tufting on a variety of backing fabrics

- Tufting designs with very small details

- Working without pressured air

- Ultra high densities (Click here to see the carpet samples)

- Nonstop Cut/Loop changeover

Pneumatic tufting gun

- Guillotine cutting principle

- Loop pile: 5mm–70 mm

- U-tuft Cut Pile: 10-60mm !

- J-tuft Cut pile: 15-100mm

- Various tufting needles: Ø4.8mm, Ø6mm, Ø8mm or Ø11mm

- Variable pile height accessories for 3D effects (Click here to see the carpet samples)

- Nonstop Cut/Loop changeover (Click here to see the carpet samples)

General Information

We offer our customers both innovative and high-quality products. 100% designed made in Germany serves as a guarantee for best quality standards – all components for our eTuft robots are sourced, built and assembled in Germany.

|

Interchangeable tufting-gun mechanism |

|

Variable pile height (3D) tufting effects (available only in pneumatic tufting head) |

|

Nonstop cut-loop changeover |

|

Works with wide range of yarns: Wool, Viscose, Bamboo, Polyester, Fancy yarns, Nylon, Linen, Cotton, Polypropylene, Polyethylene or their blends |

|

Rigid mechanical structure for high speed and accurate production |

|

Laser Pointer, synchronized with controller for precise positioning of the tufting head |

|

Camera on tufting head for easy repairing by machine |

|

Wireless Remote Control, improving the machine operator’s efficiency, as eTuft can be operated from different spots |

|

Seamlessly integrated with eDesigner carpet design software |

|

Production throughput: 1~6 Sqm/Hour (depends on design and quality) |

|

Minimum ROI (Return on Investment) within one year (subject to the customer’s production requirements and design complexities) |

Carefully designed and manufactured in Germany

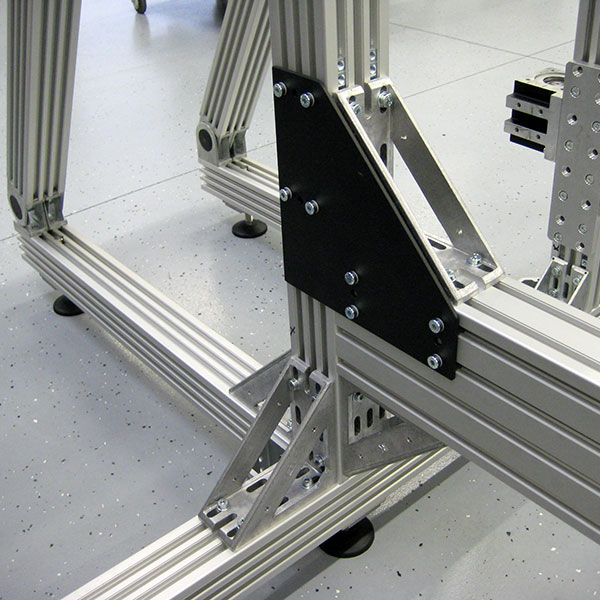

Mechanical structure

|

Carefully designed and built with German components. |

|

Rigid mechanical structure for high speed tufting without harmful vibrations. |

|

No floor preparation needed. eTuft robots can be relocated easily to meet your production needs. |

|

Over-engineered for excellent tufting quality and machine reliability (e.g. 4x linear units and 6x servo motors). |

|

Optimal penetration of tufting gun into the backing fabric by using high accuracy linear units which are driven by servo motors. (Versus other relatively primitive methods of pneumatic cylinder or manual adjustments.) |

Wireless Remote Control

Control Unit

|

Electrical cabinet and control panel with eHMI (Human Machine Interface) software in German, English, French, Turkish, Chinese, Spanish, Portuguese, Russian, Persian or in any other languages upon request |

|

Dynamic Pressure Control Mechanism ensuring optimal penetration of the tufting gun into the backing fabric |

|

Laser Pointer, synchronized with controller for precise positioning of the tufting head |

|

Camera on tufting head for easy repairing by machine |

|

Wireless Remote Control, improving the machine operator’s efficiency, as eTuft can be operated from different spots |

|

Touchscreen monitor |

|

Windows 10 Operating System |

Optional Equipments

|

Mechanical Tufting gun |

|

eGun (Hand-tufting gun) for repair works |

|

eShear (Stationary Carpet Shearing Machine) |

|

Tufting gun accessories for Ø11mm needles |

|

Additional frames for continuous production |

|

Rotating Creel |

|

Carving Device |

Production

|

Production throughput: 1~6 Sqm/Hour (depends on row distance, stitch rate and complexity of design) |

|

Maximum nominal tufting speed is 2000 Stitches/Min for pneumatic tufting head |

|

Maximum nominal tufting speed is 1200 Stitches/Min for Mechanical tufting head |

Requirements

|

Electricity: Main voltage 220 VAC 50-60 Hz single phase, 2KW power |

|

Compressed air: Air consumption 400 lit/min, min 8 bar, recommended 600 lit/min 10 bar |

Set no limits to your creativity!

Realize quick and cost-effective production!

Get fast return on your investment!

Comparison Chart

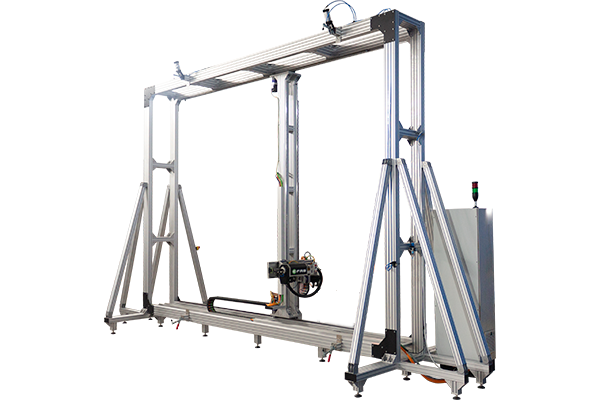

ECM-A 3×4

Effective tufting area:

3 x 4 meter (9.8 x 13.1 ft)

Construction: Gate

Structure: Aluminum

Rigidity: High

Vibration: Low

Length:730 cm

Height:440 cm

Width:230 cm

Weight: ~1,250 kg

Tufting head:

Mechanical

Interchangeable Tufting-Gun Mechanism

Variable pile height effect (3D)

Smart Cut/Loop Changeover

Dynamic Pressure Control Mechanism

Laser Pointer

Camera on tufting head for easy repairing by machine

Wireless Remote Control

Creel:Movable rotating creel

ECP+ 3×4

Effective tufting area:

3 x 4 meter (9.8 x 13.1 ft)

Construction: Gate

Structure: Aluminum

Rigidity: High

Vibration: Low

Length:730 cm

Height:440 cm

Width:230 cm

Weight: ~1,250 kg

Tufting head:

Pneumatic or Mechanical

Interchangeable Tufting-Gun Mechanism

Variable pile height effect (3D)

Smart Cut/Loop Changeover

Dynamic Pressure Control Mechanism

Laser Pointer

Camera on tufting head for easy repairing by machine

Wireless Remote Control

Creel:Fixed or Movable rotating creel

ECO TOWER 4×6

Effective tufting area:

4 x 6 meter (13.1 x 19.7 ft)

Construction: Tower

Structure: Aluminum

Rigidity: Medium

Vibration: Medium

Length:896 cm

Height:532 cm

Width:131 cm

Weight: ~900 kg

Tufting head:

Pneumatic

Interchangeable Tufting-Gun Mechanism

Variable pile height effect (3D)

Smart Cut/Loop Changeover

Dynamic Pressure Control Mechanism

Laser Pointer

Camera on tufting head for easy repairing by machine

Wireless Remote Control

Creel:Movable

MK-V 4×6

Effective tufting area:

4 x 6 meter (13.1 x 19.7 ft)

Construction: Gate

Structure: Steel

Rigidity: Very High

Vibration: Very Low

Length:842 cm

Height:550 cm (480 cm MK-III)

Width:145 cm

Weight: ~2,000 kg

Tufting head:

Pneumatic or Mechanical

Interchangeable Tufting-Gun Mechanism

Variable pile height effect (3D)

Smart Cut/Loop Changeover

Dynamic Pressure Control Mechanism

Laser Pointer

Camera on tufting head for easy repairing by machine

Wireless Remote Control