EFAB is proudly introducing the new P25 Pneumatic Tufting Head with major enhancements and improvements.

The latest P25 pneumatic tufting guns set a new standard in precision and versatility. Engineered with cutting-edge enhancements and optional accessories, this generation delivers exceptional ultra-low pile heights (~10mm before shearing) with unmatched accuracy and consistency.

This breakthrough opens up new creative possibilities for manufacturers—enabling:

- Intricate designs

- Tighter weaves

- Smoother surface finishes

Perfectly aligned with the growing demand for modern, minimalist aesthetics and sustainable production, the P25 empowers you to meet the evolving expectations of today’s flooring market.

Precision in Low Pile Tufting

Achieving ultra-low pile height has long been a challenge due to the control required—but the new P25 overcomes this with ease, delivering high-quality and stylish flooring results.

Versatility for Artificial Turf Applications

With the right accessory setup, the P25 can also tuft up to 70mm pile height, even on very thick, double-layered primary backing—making it an excellent choice for custom made artificial turf tufting where durability are essential.

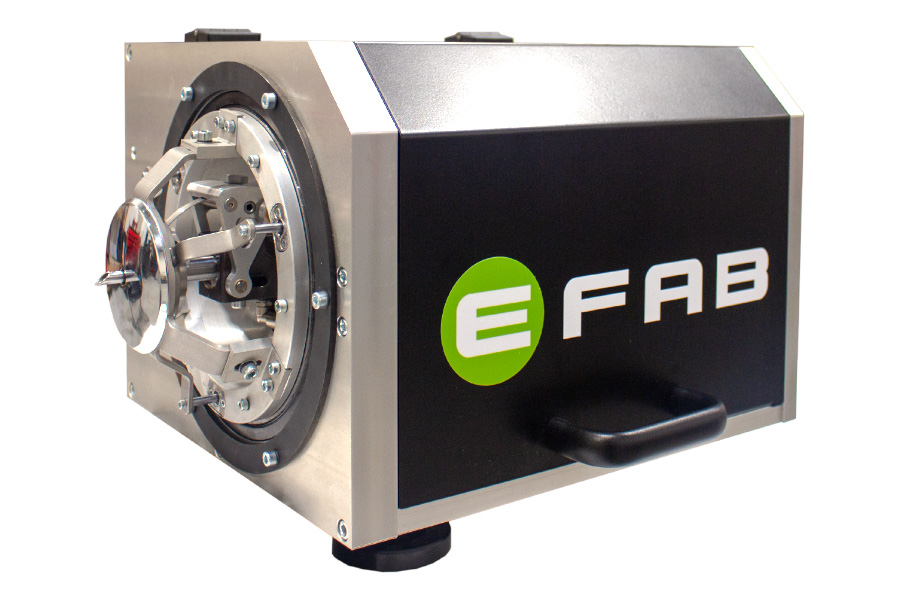

New Pneumatic Tufting Head

The new P25 Pneumatic Tufting Head has unique features as below:

- Loop pile: 5mm–100 mm

- U-tuft Cut Pile: 10-70mm !

- J-tuft Cut pile: 10-100mm

- Various tufting needles with different inner diameters: Ø4.8mm, Ø5.4mm or Ø8mm

- Variable pile height for 3D tufting

- Nonstop Cut/Loop changeover

- Rotating needle mechanism

- New adjustable stroke mechanism (10-18mm)

- New adjustable air flow and timing mechanism

- Improved yarn feeding system

- Compact and lighter than previous Pneumatic tufting head

- And more …

EFAB’s Easy Docking System: Seamless Switching Between Pneumatic and Mechanical Tufting Heads

To maximize flexibility and functionality in robotic tufting, EFAB has developed the innovative Easy Docking System — allowing users to effortlessly switch between pneumatic and mechanical tufting heads on the same machine.

With this smart solution:

- The operator can change tufting heads in minutes by simply loosening four screws.

- No electrical rewiring or adjustments required — making the process quick, clean, and efficient.

This breakthrough allows manufacturers to leverage the advantages of both tufting mechanisms within a single setup, streamlining production and expanding creative possibilities.